Evaporators are used for concentration or crystallization of liquids. In most of the cases evaporators are used to increase the solid contents of the liquid product prior to drying. This is a cost-effective method of removal of moisture. Depending on the number of effects used in an evaporator the quantity of water evaporated per kilogram of steam increases.

In this system, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat and thus saves energy and overall operational cost.

This system is widely used for

- Effective concentration of dairy products, juices, pharmaceutical items such as Vitamin C, glucose, starch sugar, maltose, maltodextrin etc.

- Wastewater recycling in chemical, pharmaceutical, food and other sectors

- Zero Liquid Discharge in Dye and Dye-stuff, Alcohols etc.

Developed from 316 grade or 304 grade stainless steel, these Multi Effect Evaporators are preferred for their fast operation, less steam consumption level and huge concentration ratio.

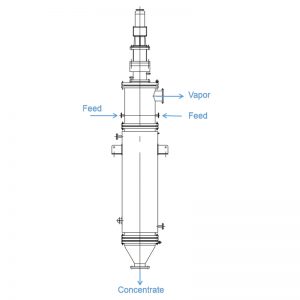

We have capacity to develop multi-effect or single effect evaporating system by making use of falling film, rising film, forced circulation and agitated thin film design to fulfil the product requirements of our client.

Reviews

There are no reviews yet.